Resource Planning Guide for ERP Implementation Success

For us, there’s nothing more exhilarating than when a new or updated ERP goes live. It’s the culmination of months — or often, years — of cross-functional collaboration and challenging work.

You might be surprised to hear, though, that a go-live isn’t the end of an ERP project.

In many ways, an ERP go-live is just the beginning.

With a new ERP, there is a laundry list of things to consider — from software features to new hardware. One of our primary roles as ERP consultants is to help our client prioritize this list into implementation phases. We get the ERP live and functional as quickly as possible in Phase I, we plan for additional features and optimization in Phase II, and we tackle backlog items as we go. We call this our crawl, walk, run approach, and it’s the best way to ensure you get a fully functional ERP without completely burning out your people.

But there is a middle transition stage between Phase I and Phase II where privately held and family-owned manufacturing companies often get into trouble. And if we don’t plan resources appropriately in the early stages of an ERP project, this is where the remaining items on the list languish … and sometimes never get implemented.

In this article, I’m going to share how we plan for and navigate this middle transition stage, so an ERP project doesn’t stall out before it’s fully complete.

Avoiding the ERP Implementation Stage of Doom

After the initial implementation (Phase I), our manufacturing clients have a functional new ERP, and individuals and departments have been trained how to use it. However, the company is still very much in triage and support mode until things settle down enough to shift into daily operations and planning the next phase.

This is where things get sticky.

If you haven’t planned thoroughly for this transition stage, you can easily get stuck here in triage/support mode indefinitely.

This is why we work with our manufacturing clients to plan ahead and train enough to make sure we’re not in triage/support mode for more than 2-3 months.

It can be hard to think that far ahead in the early planning stages of an ERP project — but it’s absolutely critical. By the time the ERP solution is implemented, the core team is exhausted. They’re ready to move on from implementation to operation, and most of them will need to start transitioning back into their day jobs. But we still need the core team to keep the ERP implementation moving into the next phase.

I’ve seen companies stuck here for six months or more, with their ERP implementation only half completed. It’s exhausting and disheartening for everyone involved, which is why I am so adamant about planning for this “purgatory” stage in advance.

How to Plan Now to Avoid ERP Purgatory Later

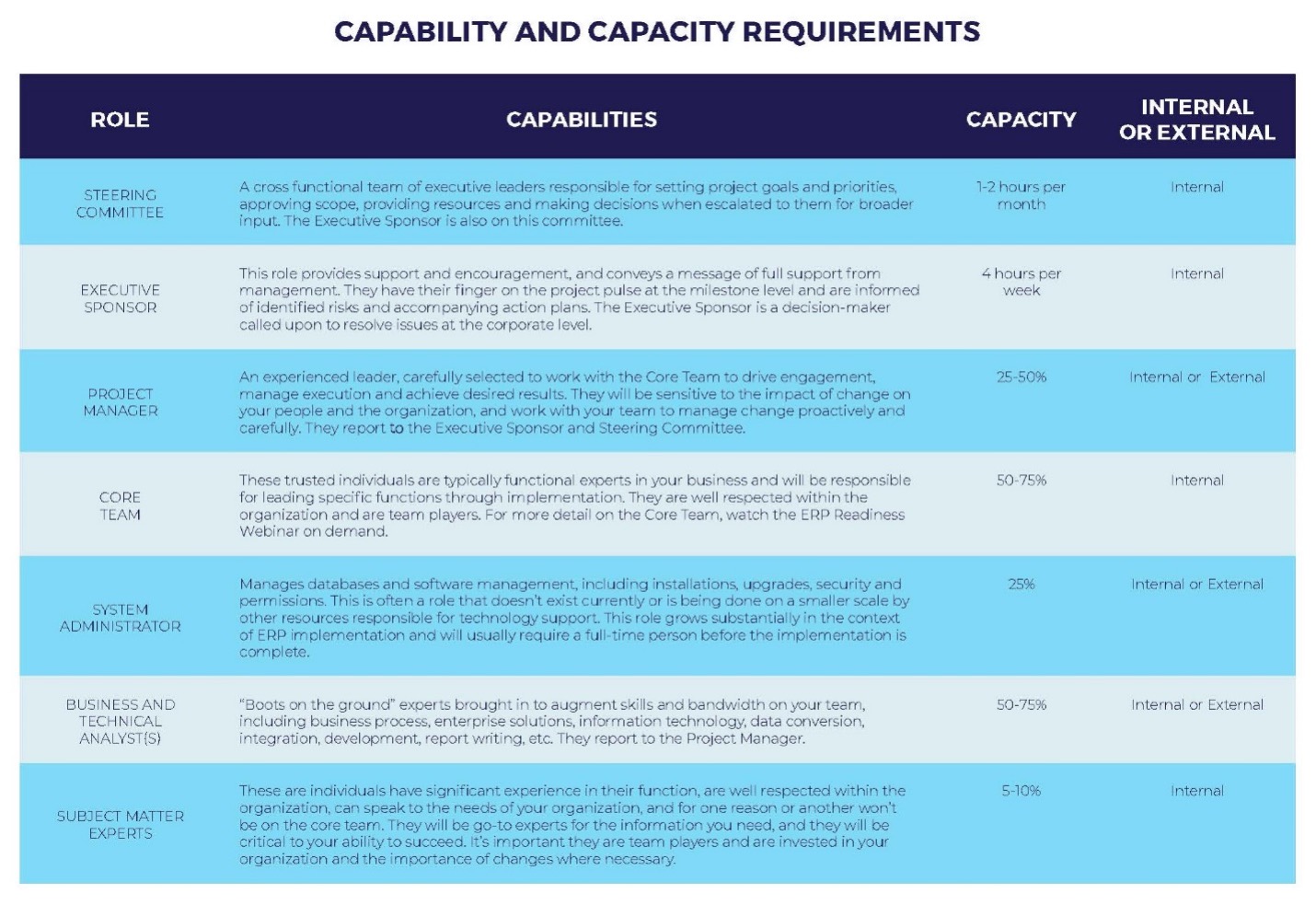

Planning for post-implementation sustainability means thinking about capabilities and capacity beyondimplementation and through optimization and support.

This chart from our ERP Readiness Assessment is a good place to start the thinking process:

In addition to planning the roles that will be required for ERP implementation and optimization, you’ll also want to think about whether those roles will need to be filled by existing internal resources, outsourced resources, or new hires.

And finally, you’ll need to think about which existing internal resources will need to go back to their day jobs after implementation — because this is going to create new gaps. If you anticipate those gaps, you can plan ahead so there’s no lag time in getting new resources in place.

It Takes a Village to Plan an ERP Project

This is a lot to think about! The sooner you start having these conversations, the better. In our experience, resource planning works best as an iterative process starting before and going through implementation.

This advanced planning pays huge dividends for privately held manufacturing companies. It saves them time, cost, and most importantly, sanity.

Thinking about a new or upgraded ERP for your manufacturing company? Let’s talk about what you’ll need to plan for. Schedule a complimentary consultation right now.

ERP Readiness Self-Assessment

Is your organization ready for a new or upgraded ERP solution? Find out with this complimentary self-assessment.

Doing Business Better

You strive for excellence, believe in your people, and want to do things right the first time. And you know that you need help to get to the heart of your business challenges and make the best choices for the future of your privately held manufacturing and distribution company. That’s where we come in.

We help you focus and find exactly the right path to accelerated growth and sustainable success — from your people to your processes to your ERP software.