The True ERP Challenge in 2023: Aligning People, Process and Technology

This year, the hottest topics in the enterprise resource planning (ERP) world are all about technology — everyone seems to be talking about artificial intelligence and rapid implementation methodologies.

And while the software is changing rapidly — and the tech part of ERP is exciting — what often gets left out of the conversation is the human aspect of ERP implementation.

At Syte Consulting Group, we firmly believe that the success of ERP solutions comes from an awareness of the interconnectedness between people, process and technology.

In our conversations with privately held manufacturing companies, we’re hearing that many organizations are facing post-implementation challenges and struggling to get a return on their ERP investment — and technology is not the problem.

These companies are struggling with issues around how well people are prepared to go live, how they have been trained to operate the new solution and how they can optimize the technology for full benefit.

Read on to find out how these trends are showing up for companies in 2023, and the best practices we recommend for leveling up your people so you get maximum return on your software investment.

To give context to the conversation about people and resources, let’s start off by looking at the biggest recruitment and retention trends happening in the U.S. right now — in the overall labor market, and specifically in the manufacturing sector.

The State of Employment in the U.S.

In August 2023, the U.S. Bureau of Labor Statistics reported that job openings increased to 9.6 million, which indicates a growing demand for labor across various industries.

Hires remained relatively stable at 5.9 million, and the hiring rate stayed at 3.7%. Total separations, which include quits, layoffs, discharges, and other separations, also remained largely unchanged at 5.7 million.

Companies are trying to fill a lot of roles. What’s causing the recruiting and retention challenges?

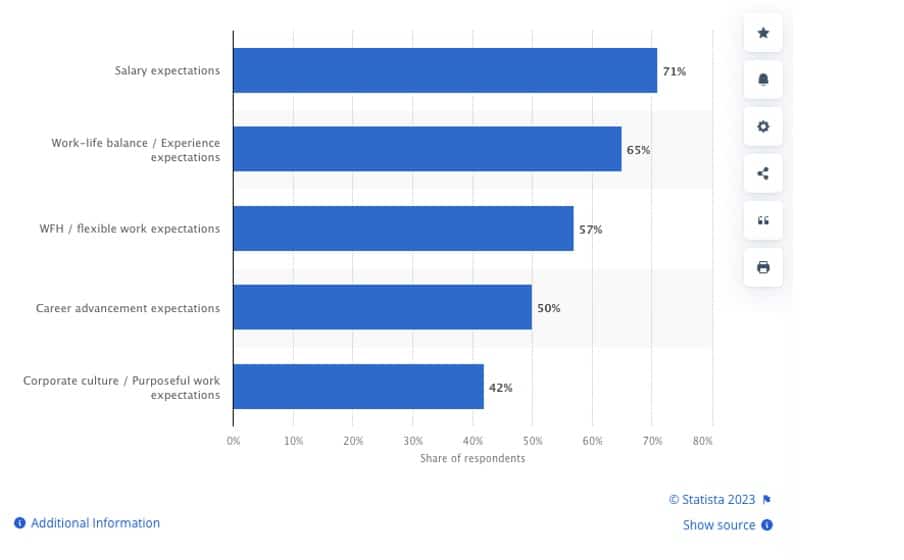

In a Statista survey, approximately 50% of human resource professionals reported that rising salary expectations and a lack of career advancement opportunities were negatively impacting hiring and retention efforts.

Meanwhile, what does the manufacturing job market look like?

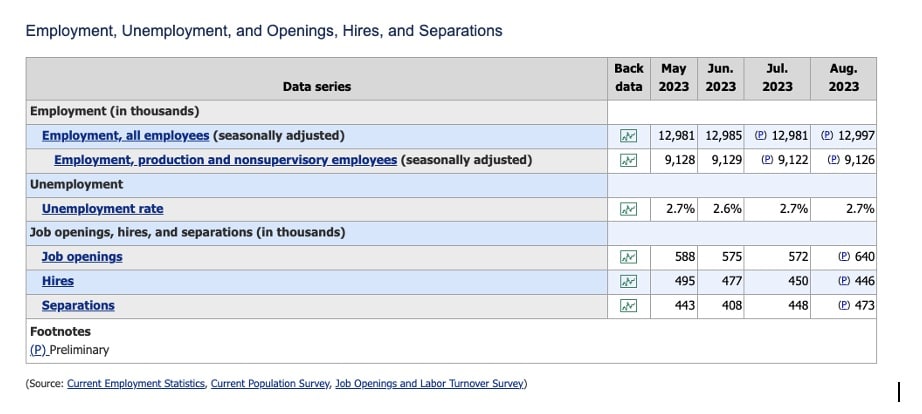

As of August 2023, the unemployment rate in the manufacturing sector was 2.7%, compared to the overall U.S. unemployment rate of 3.8%. Job openings rose to 640,000 (up from 572,000 in July).

These statistics show that the demand for manufacturing labor remains high, and seems to be growing month over month.

Some economists believe manufacturing employment could be getting a boost from U.S. policy changes that support semiconductor production, domestic infrastructure and clean energy development.

Mark Zandi, chief economist at Moody’s Analytics, said, “Policy has really been an increasingly powerful tailwind of the manufacturing base.”

Others believe shifted economic demand has also played a part. A journalist on the Waupaca Foundry blog states:

“The years that followed [the Great Recession of 2008] are considered the recovery, which led up to the 2020 recession. Consumer demand slowly returned as Americans rebuilt their credit scores and made big purchases — like a new vehicle — they may have otherwise put off during the recession. That helped support jobs in manufacturing for American workers assembling the latest and greatest trucks and SUVs.”

What We’re Hearing From Privately Held Manufacturing Companies

Syte Consulting Group speaks to a lot of privately held and family-owned manufacturing and distribution companies during and after ERP projects, and we hear about a wide range of post-implementation problems.

One of the most notable issues is the struggle to achieve the anticipated return on investment (ROI) after implementing an ERP system.

Many times, even two to five years post-implementation, companies are still experiencing system adoption issues. Many still rely on spreadsheets for tasks like material requirements planning (MRP), which should be facilitated by the ERP system.

This sometimes occurs because of a lack of training and documentation during the implementation phase, and the company is still feeling the pain years down the road.

And again, that’s not a technology problem — that’s an issue with people and processes.

We’re also seeing high turnover in the manufacturing sector, and many companies are struggling to recruit talent for open roles. Human resource problems aggravate existing training deficiencies. New employees struggle because there isn’t a proper knowledge transfer mechanism, making learning curves steeper.

One significant consequence of these challenges is companies’ unpreparedness for the “operate and optimize” phase post-implementation. This crucial phase is when initial implementation goals that were postponed during the hustle and bustle of the ERP launch can be revisited and executed.

But if the team is not properly staffed and trained, this phase can really bog down an organization.

Compounding this industry-wide staffing challenge are growing pains for privately held and family-owned manufacturing companies. When a company is ready to implement an ERP, it is a clear sign that they are maturing — and with that maturity comes new staffing needs. The roles that got the job done are not the same roles required now that the company is larger and more complex than the last time systems were implemented.

Companies often make the mistake of thinking they’ll pull staff resources temporarily for an ERP implementation, those employees will do double duty until the implementation is complete, and then those people can go back to their operational roles. But the reality is that to achieve optimal ROI, ERP solutions need to be continuously optimized—and that requires ongoing allocated resources.

Knowing this and planning for it from the beginning is the only way to avoid “operational limbo,” where they have a backlog of projects to execute, but they’re hampered by lack of resources, training deficiencies and turnover. In this situation, the optimization that leaders envisioned when they implemented the ERP takes much longer than they pictured, and the path to realizing the ERP system’s full ROI becomes murkier.

Best “People” Practices for ERP Implementation

So if those are the issues we’re seeing in the field — what are the solutions?

Here are our recommended best practices for supporting ERP systems effectively:

- Start planning early: Talk about people and processes during ERP selection and the period before going live. Anticipate and prepare for the “operate and optimize” phase well in advance.

- Think about future needs: What additional resources and structural changes might be required to optimize the ERP implementation?

- Practice change management during and after: An ERP project is primarily a change management initiative, and it impacts individuals company-wide. Your team will deal with emotions ranging from excitement to resentment, so you’ll need to guide people through the effects of the new technology.

- Remember that ERP implementation is just the start: Post go live, be prepared for backlog tasks, feature adjustments and emerging challenges. Adopt a continuous improvement perspective and align ERP evolution with business growth. Line up the resources to have a post go-live team for future projects. Prioritize ongoing support, training and maintenance in your implementation plan to ensure smooth daily operations.

Here are some resources that can help you get ready for your own ERP implementation:

Resource Planning Guide for ERP Implementation

Syte’s Holistic Approach to ERP Implementation

Success in ERP implementation goes beyond choosing a technology solution. Privately held manufacturing companies also need to train, equip and consistently back the people at the heart of the change.

At Syte Consulting, we help our clients align their teams, processes and tech throughout the ERP journey — from the first brainstorming meetings to the final finish line (and beyond).

Get in touch today to find out how we can help you.

ERP Readiness Self-Assessment

Is your organization ready for a new or upgraded ERP solution? Find out with this complimentary self-assessment.

Doing Business Better

You strive for excellence, believe in your people, and want to do things right the first time. And you know that you need help to get to the heart of your business challenges and make the best choices for the future of your privately held manufacturing and distribution company. That’s where we come in.

We help you focus and find exactly the right path to accelerated growth and sustainable success — from your people to your processes to your ERP software.